Enthalpy rotary heat exchangers

Air flow through rotary heat exchanger

Operation

Rotary heat exchangers transfer energy through a rotating storage mass, which is alternately heated by one air stream and cooled by the other. They can transfer both temperature and humidity between air streams.

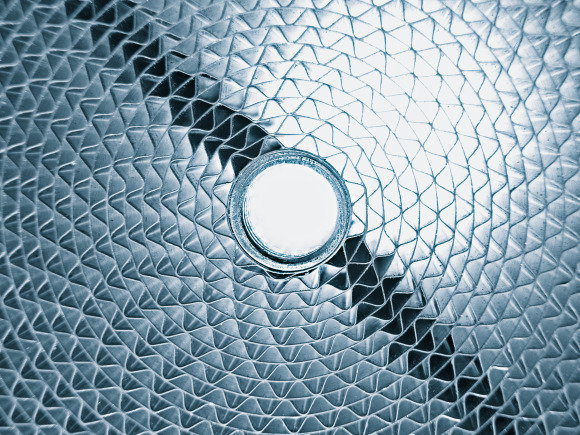

The storage mass consists of aluminium foil. A smooth and a corrugated foil are wound on top of each other to form a wheel of sinusoidal channels. Warm air and cold air flow through these alternately and thus transfer the heat between the two air streams.

Two different aluminium foils are used for the production of the storage mass. The corrugated foil is untreated, the smooth foil is coated with molecular sieve 3 Å. The efficient humidity recovery system ensures that humidity is not lost from the extract air. The room air is not as dry and additional air humidification systems can be designed with smaller dimensions.

Enthalpy rotary heat exchanger design

Emån (SE3)

Emån SE3 is our enthalpy rotary heat exchanger. This ensures a high level of humidity transfer in the transition seasons and during the winter.

With its effective humidity recovery, the Emån SE3 prevents the unpleasant consequences of overly dry air. It comprises a special combination of a hygroscopic surface for selective humidity transfer and an aluminium foil. This hybrid design saves you investment costs while ensuring optimal humidity transfer all year round.

Areas of application

In the enthalpy wheel design (Emån), the exchanger is partially coated with a hydrophilic material and built for use in comfort ventilation systems.

Application limits

- Diameter: 500–4200 mm

- One-piece Ø500–2600 mm, segmented Ø950–4200 mm

- Air flow rate from approx. 200 to 150 000 m³/h

- Differential pressure between the air streams max. 1000 Pa

- Pressure drop for 1-piece wheels max. 300 Pa

- Pressure drop for segmented wheels max. 400 Pa

For the perfect indoor climate.