Condensation rotary heat exchangers

Air flow through rotary heat exchanger

Operation

Rotary heat exchangers transfer energy through a rotating storage mass, which is alternately heated by one air stream and cooled by the other. They can transfer both temperature and humidity between air streams.

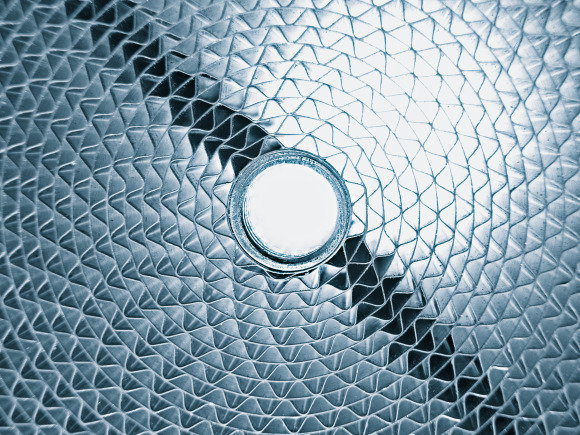

The storage mass consists of aluminium foil. A smooth and a corrugated foil are wound on top of each other to form a wheel of sinusoidal channels. Warm air and cold air flow through these alternately and thus transfer the heat between the two air streams.

Their storage mass does not have any hydrophilic coating. Therefore, condensation wheels only transfer humidity during the winter when condensate forms in the storage mass on the extract air side and is then taken up on the supply air side. As a result, humidity efficiency is directly dependent on the amount of condensate on the extract air side and the amount of humidity taken up on the supply air side. The maximum humidity transfer potential is the difference between the humidity content of the extract air and the dew point of the fresh air temperature.

Condensation rotary heat exchanger designs

Viskan (ST3)

The Viskan ST3 rotary heat exchanger was developed on the basis of our tried-and-tested ST1 wheel. The new storage mass also ensures improved efficiency with an optimised aluminium foil. The pressure drop remains at a low level. With its high efficiency, the new Viskan ST3 is suitable not only for standard applications, but also for high-end central air-conditioning units.

ST1

SC1

Areas of application

In the condensation wheel design, the exchanger is made of untreated aluminium and is ideally suited for use in ventilation units for residential buildings, offices, hotels, etc. without humidification and mechanical cooling.

Application limits

- Diameter: 500–4200 mm

- One-piece Ø500–2600 mm, segmented Ø950–4200 mm

- Air flow rate from approx. 200 to 150 000 m³/h

- Differential pressure between the air streams max. 1000 Pa

- Pressure drop for 1-piece wheels max. 300 Pa

- Pressure drop for segmented wheels max. 400 Pa

Experience our diversity.